- Home

- Startup news

- FlyBlast: on a mission to solve meat

FlyBlast: on a mission to solve meat

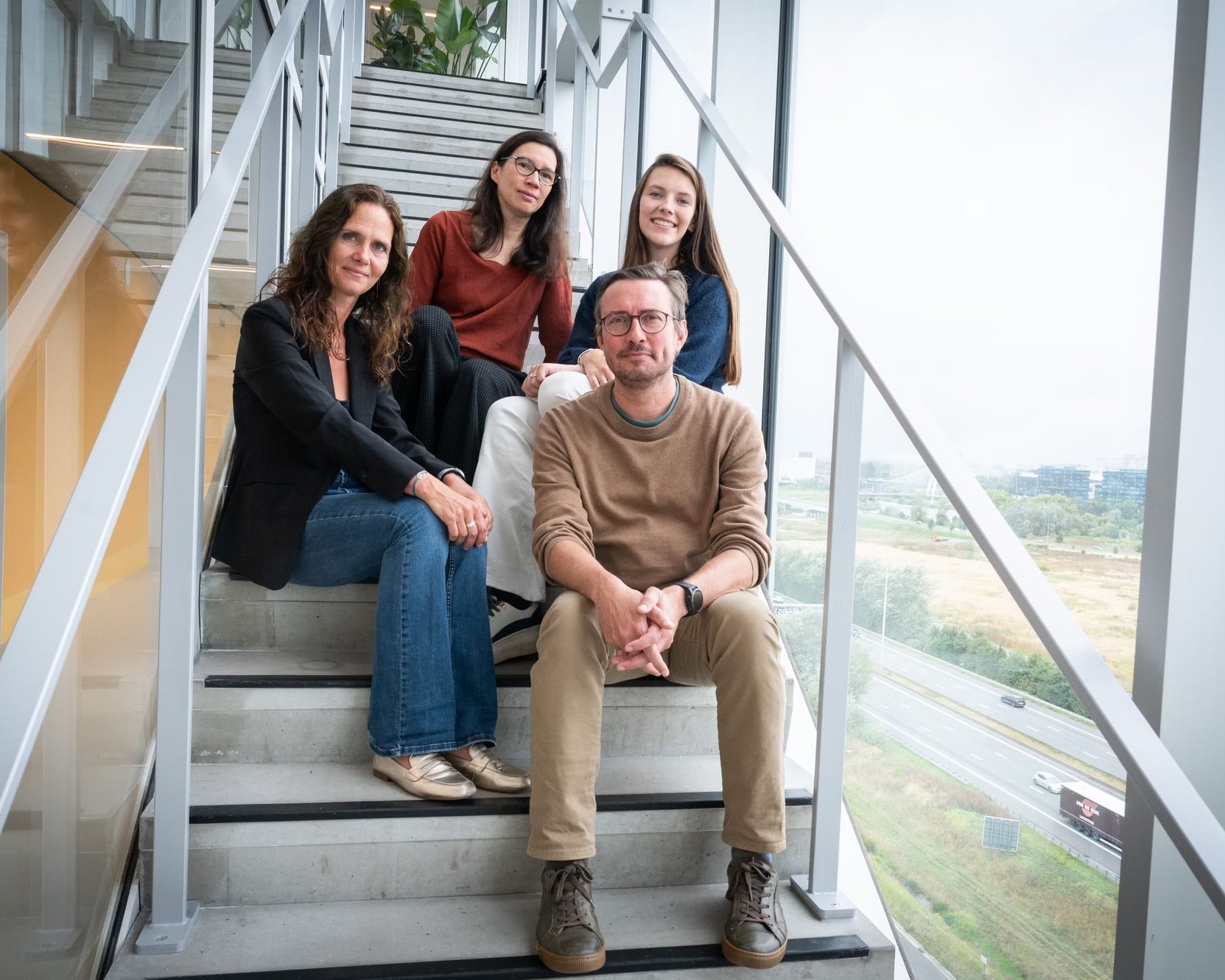

How can flies help to lower barriers for cultivated meat? Seasoned entrepreneurs Johan Jacobs, Leentje Croes and Paul Mozdziak combine their expertise in cultivated meat and insect bioconversion into a win-win innovative endeavour. Meet FlyBlast—the latest biotech startup backed by biotope by VIB.

FlyBlast has a big and bold goal: to solve meat. That’s because even though its founders like a steak or burger from time to time, meat as we know it today is a problem.

“All three of us eat meat—we even enjoy it,” says Johan Jacobs, CEO of the new startup, “but of course we are very conscious of the fact that current meat production and the growing global demand are slowly destroying the planet.” It’s the overarching reason why he co-founded FlyBlast, together with Leentje Croes and Paul Mozdziak.

The trio wants to make a positive impact on the environmental footprint of carnivores, but having taken companies from start to exit before, they understand all too well that societal and economic impact go hand in hand.

Driving down the cost of cultured meat

“The alternative meat industry is maturing, but currently the cost of cultivated meat is simply prohibitive for it to become a mainstream product and viable alternative to traditional meat,” says Leentje Croes. She is bringing in her wealth of experience at the helm of operations at Piece of Meat, the promising Belgian cultured meat company that unfortunately had to close down last year.

“Alternative meat is typically grown in an expensive growth medium, which is the main driver behind the high production costs. If we could bring these costs down to a more competitive price range, there is no doubt that cultivated meat will boom.”

In its essence, growth medium is a cocktail of nutrients (sugars, proteins, lipids) and valuable molecules, including recombinant proteins and growth factors. One of its common components is fetal bovine serum, which is harvested from fetuses taken from pregnant cows during slaughter.

“Besides the high costs of traditional growth medium, there is also the ethical and animal welfare component, which is completely at odds with the entire principle of cultured meat,” adds Paul Mozdziak, who has a strong academic background and worked with Leentje Croes before, during his time as Chief Scientific Officer at Piece of Meat.

Luckily, there are alternative ways to produce growth medium. “You could use bacterial platforms or yeast, for example. There are also several companies that explore plant-based substitute ingredients for growth medium.” But the team at FlyBlast is looking in another direction.

Subscribe

Subscribe for Exclusive Updates and Exciting News!

Thank you

You are subscribed to my newsletterIf we could bring the costs down to a more competitive price range, there is no doubt that cultivated meat will boom.

Leentje Croes

Making Black soldier flies’ work pay off

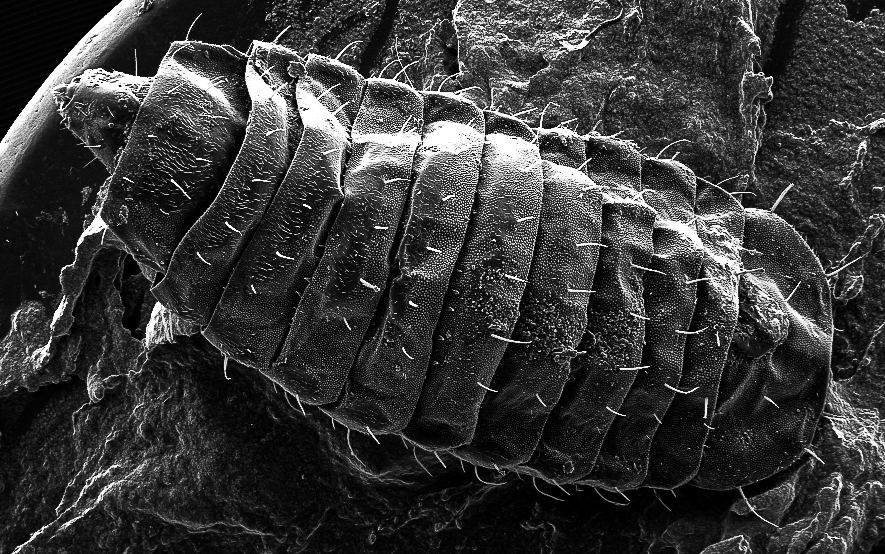

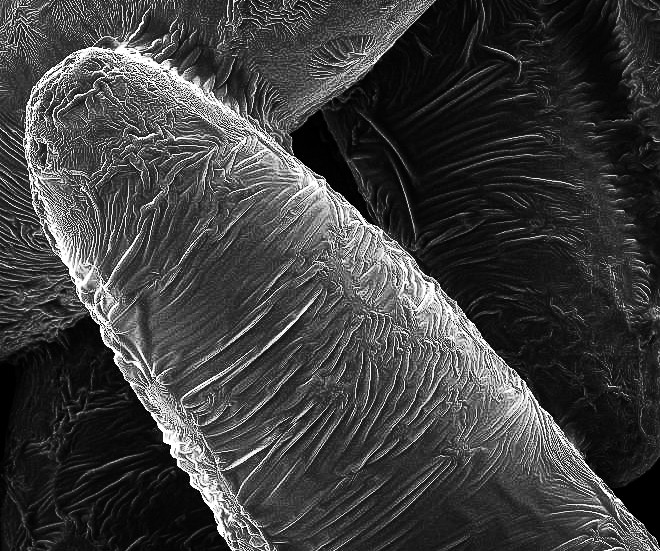

FlyBlast’s technology platform is centered around the Black Soldier Fly, a slender insect whose larvae feed on decomposing organic matter. “These larvae consume a wide range of organic materials, from food scraps to manure, compost or decaying plant matter. A diet that makes them valuable partners in waste management,” explains Johan.

That’s why he founded Millibeter 12 years ago, a startup focused on the bioconversion of organic waste into protein and lipids. “With Millibeter, we used insect bioconversion to turn organic waste into feed, which is a great approach that has since become a reality. However, the insect bioconversion industry is not profitable enough. If we really want to scale this biotechnology, it is crucial that we find ways to extract more value from each ton of insect production.”

A pathway to revenue

Leentje, Paul and Johan realized that there was a joint solution to these two challenges—all while also creating scientific impact. “If we succeed in producing good growth medium using Black Soldier Flies, in a way that brings down the cost far enough, we will make insect bioconversion far more profitable and at the same time will enable cultivated meat to become a mainstream alternative to traditional meat,” says Paul.

His expertise in cell culture and molecular biology is instrumental in achieving this milestone. As FlyBlast’s Chief Technology Officer, Paul has already taken several steps into the right direction. The team is confident to reach a proof of concept for their first product this year.

“We are negotiating partnerships with cultivated meat companies to validate our ingredients, and in a next phase hope to raise the money to build our own factory.”

At the same time, Paul will go back to the drawing board, to broaden the scope of FlyBlast’s technology platform. “We are just getting started. We have a broad pipeline of products to explore.”

It is crucial that we find ways to extract more value from each ton of insect production.

Johan Jacobs

More News

The fundraising mirage

Typcal is brewing the future of pragmatic protein

AmphiStar secures €12.5m EIC funding

biotope recap: Summer edition

Annick Verween on the VCo2 podcast

2024 wrapped

Networking with cohort six

B’ZEOS celebrates seed round milestone

Tackling food waste at its source

The value of good mentors

Meet our Spring ‘24 cohort

His son’s allergy turned this father into a founder

Biosurfactants from food waste? Meet AmphiStar

Probitat interview

B’ZEOS: sustainable packaging made of seaweed

Elogium: Poultry probiotics for safer food

Launch of Biotope ventures fund

Bolder Foods: non-dairy cheese for a better world

BioVox article

Have you got what it takes?

- Pressure-test your biotech with expert feedback

- Align your team and sharpen your strategy

- Turn your startup into an investment-ready business